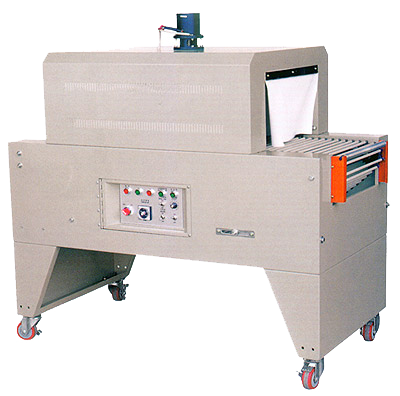

Shrink Tunnel

SA-313 PVC / POF Shrink Tunnel (Mini type) and SA-316 PVC / POF Shrink Tunnel (Standard type)

Tunnel

SA-313 PVC / POF Shrink Tunnel (Mini type) and SA-316 PVC / POF Shrink Tunnel (Standard type)

Tunnel Specifications

PVE/POF Shink tunnel

- Machine constructions use S-41 steel material.

- Machine frames formed up by model.

- Specified spare parts kit.

- Live roller rod conveyor.

- Speed changeable motor with speed desired & adjusted easily.

- Fully re-circulating heating air.

- Highly efficient heating up with good separations.

- Temperature controlled automatically.

- Temperature variable with easily operation.

- SUS thermocouple systems.

- SUS 304 stainless steel inner tunnel.

- SUS 304 stainless material wires & terminals, covered with ceramic guards.

- CE model available.

Dimensions : Tunnel (Roller Conveyer 18×30)

| Total | MM | Inch |

|---|---|---|

| Length | 1200 | 47 |

| Width | 790 | 31 |

| Height | 1310 | 51.5 |

| Hot Chamber Box | ||

|---|---|---|

| Length | 800 | 31.5 |

| Width | 430 | 17 |

| Height | 240 | 9.5 |

Suitable product size 360 mm X 300 mm

14″ x 12 “

Dimensions : Tunnel (Belt Conveyer 18×30)

| Total | MM | Inch |

|---|---|---|

| Length | 1200 | 47 |

| Width | 800 | 31 |

| Height | 1380 | 54 |

| Hot Chamber Box | ||

|---|---|---|

| Length | 800 | 31.5 |

| Width | 430 | 17 |

| Height | 290 | 11.8 |

Suitable product size 360 mm X 300 mm

14″ x 12 “

Dimensions : Tunnel (Roller Conveyer 18×40)

| Base | MM | Inch |

|---|---|---|

| Length | 1500 | 59 |

| Width | 850 | 33.5 |

| Height | 1460 | 57.5 |

| Hot Chamber | ||

|---|---|---|

| Length | 1000 | 39.5 |

| Width | 470 | 18.5 |

| Height | 390 | 13.5 |

Suitable product size 360 mm X 300 mm

14″ x 12 “

Characteristics

- Indigenously Designed & manufacture Semi Automatic Shrink Packaging Machines.

- Speed up to 10 to 15 Product Per Min.

- Uniform Air Flow Around Product.

- Auto Tuning Of Heat & Air Flow.

- M.C.B provided for safety purpose.

- Auto cool provision given in the circuit so the machine automatically turns off after 20 to 30 mins.

Applications

Suitable for food, gifts, hardware, daily-use products, electronics, electrical industries, medicines, bamboo ware…etc.